Highly efficient UREA pumps for your exhaust gas purification system in GenSets

Optimize the SCR systems in your (emergency) power generators with SCHERZINGER UREA dosing pumps

SCHERZINGER pumps for optimum urea solution injection in exhaust gas purification systems for diesel and gas-powered GenSets

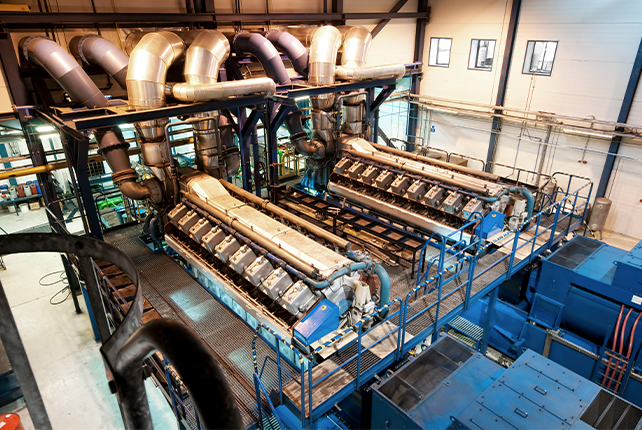

Power failures, for example in data centers, hospitals or industrial plants, are tantamount to a disaster. For this reason, an uninterruptible power supply using so-called GenSets is essential. Modern emergency power generators or diesel generators require reliable and maintenance-free components in order to be ready for immediate use in an emergency. Our specially developed gear pumps ensure the precise dosing of AUS40, UREA, AdBlue® and other urea solutions in different quantities for efficient exhaust gas aftertreatment. In this way, we help to ensure that your critical infrastructure functions smoothly even in exceptional situations.

Optimum integration for SCR and DeNOx systems

Our gear pumps are flexibly configurable and can be easily integrated into existing exhaust gas cleaning systems for emergency power generators. Regardless of whether you are a manufacturer or supplier of gas turbines, engines, exhaust systems or GenSets: SCHERZINGER offers customized solutions for your specific requirements. Our pumps are extremely robust, absolutely reliable and can be used in SCR applications in both gas engines and diesel gensets. Our experienced team of engineers will support you in selecting and implementing the ideal dosing pump to ensure seamless integration into your exhaust systems.

SDU 2876 Basic SDU 2876 Basic | |

|---|---|

| Repeatability | +- 2,5% |

| Dosing accuracy | +- 35% vom E.W. |

| Max. Conveyed amount | 15,9 GPH (US) |

| Max. Differential pressure | 101,5 psi |

| Triggering | CAN / 4..20 mA |

| Integrated pressure sensor | no |

| Integrated temperature sensor | no |

| Bypass for optimal intake | no |

Mono Mono | |

|---|---|

| Repeatability | +- 1,5% |

| Dosing accuracy | +- 20% vom E.W. |

| Max. Conveyed amount | 14,5 GPH (US) |

| Max. Differential pressure | 116 psi |

| Triggering | CAN / 4..20 mA |

| Integrated pressure sensor | yes |

| Integrated temperature sensor | yes |

| Bypass for optimal intake | yes |

SDU 2876 Basic SDU 2876 Basic |  Mono Mono | |

|---|---|---|

| Repeatability | +- 2,5% | +- 1,5% |

| Dosing accuracy | +- 35% vom E.W. | +- 20% vom E.W. |

| Max. Conveyed amount | 15,9 GPH (US) | 14,5 GPH (US) |

| Max. Differential pressure | 101,5 psi | 116 psi |

| Triggering | CAN / 4..20 mA | CAN / 4..20 mA |

| Integrated pressure sensor | no | yes |

| Integrated temperature sensor | no | yes |

| Bypass for optimal intake | no | yes |

An SCR system reduces NOx emissions from exhaust gases produced during the combustion of diesel and gas engines. The “Selective Cathalytic Reaction”, SCR for short, uses reducing agents such as UREA, urea, Adblue® or ammonia water, which react with nitrogen oxides. In the process, the nitrogen oxides are converted into molecular nitrogen (N2), water (H2o) and carbon dioxide (CO2), so that the emissions emitted are pollutant-free.

The Scherzinger dosing pumps are suitable for exhaust gas systems in emergency power generators, so-called GenSets. These are adapted to your individual SCR system configuration to ensure an uninterrupted power supply to your emergency power generators or diesel engines. The Scherzinger dosing pumps can also be ideally customized and configured for retrofitting.

In any case! With our decades of experience in the field of pump construction, we provide our customers and partners with comprehensive support in the form of expert advice and practical solutions. One of our great strengths lies in optimally adapting the pumps and applications we develop to your specific system or area of application. In other words: you provide the requirements, we deliver the right solution. If you want to operate an SCR system that perfectly matches your exhaust gas system, we are the ideal partner for the dosing pump. Our gear pumps reliably deliver AdBlue® and help to reduce the emissions of your exhaust system.

The Scherzinger dosing pumps enable Adblue® injection at both low and high operating pressures. In low-pressure systems up to approx. 6 bar, the urea or ammonia water is efficiently swirled with additional compressed air. For operating systems that work with a higher operating pressure, the UREA or Adblue® is atomized by the liquid pressure alone at around 7-10 bar and injected directly into the exhaust gas flow via pulsed injectors.

For the best possible performance of a gear pump used to pump UREA in an exhaust gas cleaning system, correct installation is crucial. It is recommended to install the pump at the level of the tank with the inlet. This allows a constant and even flow of liquid to the pump, reduces stress on the pump components and ensures reliable and efficient operation. Such an installation also helps to avoid possible suction problems and ensures that the pump always remains operational in critical situations.

Scherzinger pumps are supplied with a CE declaration of conformity or a declaration of incorporation and meet the highest quality and safety standards. Our gear pumps help to meet the requirements of the Ordinance on the Implementation of the Federal Immission Control Act (BImSchV) and the Industrial Emissions Directive (IED). In addition, they are installed in exhaust gas purification systems that comply with the European Stage V emission standards as well as the American EPA Tier 4 Final and New Source Performance Standards (NSPS).

The dosing pumps are available in different versions, based on two different sizes of gear pumps. These enable reliable coverage of AdBlue® flow rates from 0.5 to 1500 liters per hour. This means that engines with an output of several hundred kilowatts up to 10,000 kW can be supplied. This is achieved by using different pump sizes either individually or combined in parallel.

Both 24V DC motors and various three-phase motors suitable for all common mains voltages (e.g. 230/400V, 50Hz) can be used to operate the pumps.

The pumps can be connected to their electronics as a pump/motor unit via a plug connection. Alternatively, a master controller specially developed by Scherzinger for the application can be used. The connection to the ECU (Engine Control Unit) is made via a CAN signal with the J1939 protocol. The baud rate can be adapted to customer requirements. Other bus systems such as CANopen, Profibus, Profinet, EtherCAT etc. are also available for industrial applications.

![[Translate to English:] Bild von Nicola Knie einem Ansprechpartner und Pumpen-Experten von SCHERZINGER Pumpen.](/fileadmin/_processed_/a/5/csm_Scherzinger_Ansprechpartner_NicolaKnie_f6f6a09047.png)

![[Translate to English:] Bild von Nicola Knie einem Ansprechpartner und Pumpen-Experten von SCHERZINGER Pumpen.](/fileadmin/Ansprechpartner/Scherzinger_Ansprechpartner_NicolaKnie.png)